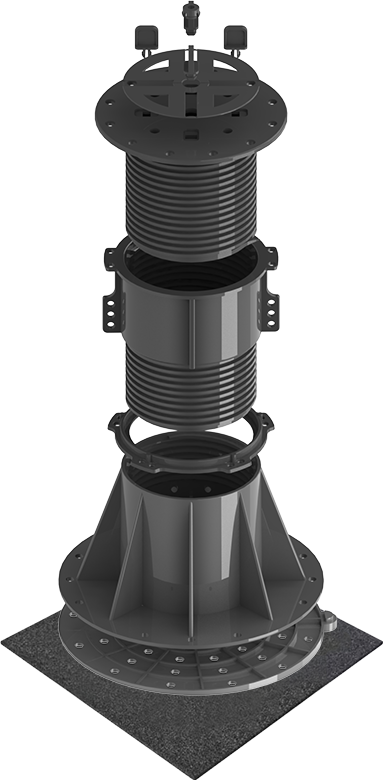

Tile pavement or Lath pavement is possible with either placing auxiliary equipments or joint strips/carcass assembly equipments on top pedestal unit’s holes and adjustable gaps. Code: HEAD

Coupler must be used when system is longer than 180 mm. These auxiliary parts can be applied more than one at the same unit. Electirical lines and water lines can be attached easily on the units. This system gives technical benefits and clear transportation.

Code: T-C

Extruding lock is usually used in high grades. This equipment avoids adjusment corruptions caused by long run vibrations.

Code T-L

There is no need to stabilize the bottom pedestal on the surface due to its broad diameter. Still there are number of gaps for making unit stable if desired. Corner and edge details have trim lines to solve distance problems. Bottom edges have bevels to give smooth touch on insulation.

Code: BASE

Slope corrector, working with bottom pedestal, avoids pressures of drain slopes on plates. Slope corrector can tolerate an degree of angles. Alternatives of 1% and 2% available

Code: T-SC

Made from EPDM, orthopedics floor pad can absorb vibration caused from rough surfaces.

Code: T-P

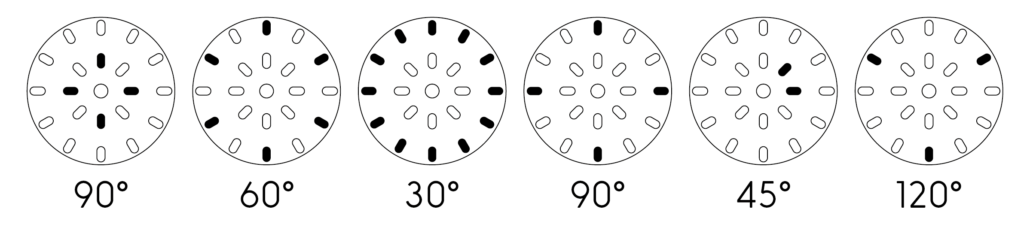

Setting Ranges

Auxilary Products

This application needs using of shims and four alternatives. According to pavement plan, multiple angle occupation is doable.